Welcome to the Jordon Research Group

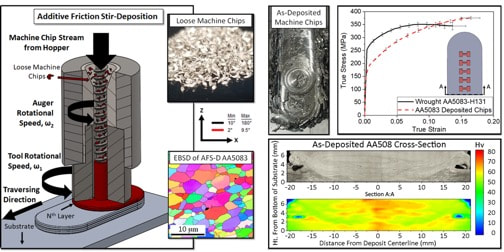

The objective of Dr. Jordon's research group is to establish high fidelity engineering models that are motivated through process-structure-property relationships. Here, we look to understand fundamental links between microstructure and bulk material response through the use of state-of-the-art characterization tools and numerical simulations. By capturing the underlining mechanisms, we can make high fidelity predictions of the mechanical performance of materials and structural components.